1. Can the packaging bags be customized for me?

Yes, we provide a wide range of standing up pouchs with custom

sizes, formats, materials, printing and convenient features.

2 What are your Quality System regulations?

Our quality systems are rooted in ISO principles & FDA GMP

requirements, and specific elements include (but are not limited

to) the programs and policies listed below:

Supplier Qualifications / Raw Material Qualifications; Incoming

Materials Management ; Document Control / Letters of Certification/

Certificates of Analysis ;

GMP Practices & Requirements / Preventive Maintenance Program /

Pest & Insect Control / Food , Beverage & Jewelry Policies /

Process Water Verification / Glass & Brittle Plastics Policies ;

Product Recall & Mock Recall /Process Risk Review / Supplier &

Customer Audits / Internal & Third Party Audits / Non-conforming

Materials / Product Holds /Complaint Management / Customer Change

Notifications etc.

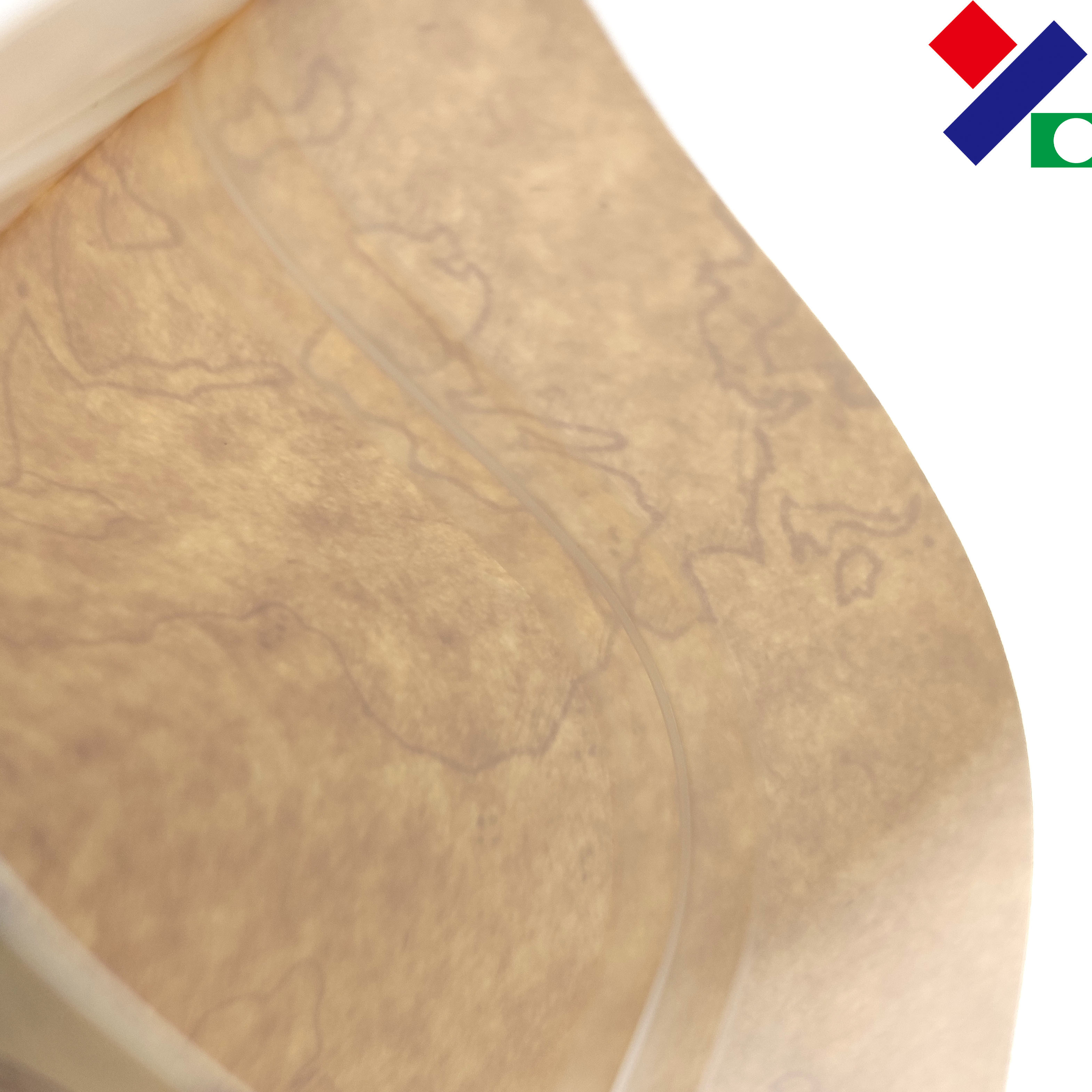

3. What are two different types of stand-up pouches?

One type is doypacks or doy type bags with a bottom gusset sealed

in an oval shape, the other type is K seal or plow bottom bag in

which the folded bottom gusset is sealed on four corners to form

self supporting stand up bottom. Both of these two types can keep

an upright standing for brand display.

4. What service do you offer when placing an order?

We can offer a full service pack from pouch sizing, material

engineering, custom printing, pouch converting, packing and

shipping. One of the main service provided in YC Packaging is

custom printing.

5. What is reverse printing?

Most laminated plastic pouches are printed by means of reverse

printing. Reverse printing is the process of printing on the back

side of a clear substrate.

In the following process, the print will be sandwiched between the

outside substrate and the rest of the structure, offering scuff and

chemical migration resistance. When the outer substrate is mounted

to the remainder of the structure, it will be right reading.

6. How is your printing process going on?

The general printing rocures are as follows :

(1): A print production worker receives a job order and takes note

of the specifications. They begin the setup process by installing

the correct cylinders, preparing the ink, and other job-specific

specs.

(2): Once the rolls of film arrive, a single roll is loaded onto

the machine and the tension is adjusted.

(3): After once cycle is complete, the worker cuts a sample piece

to analyze color accuracy.

Color accuracy is confirmed by looking at the sample through a

light box, which emits a special lighting setup that has been

adopted as an industry standard.

The workers in the printing department make decisions according to

the sample artwork and PMS color guide book.

(4): Workers are constantly monitoring the accuracy of the artwork

throughout the entire job order. Since the machines run at an

accelerated rate, workers look through a scanner, which can slow

down the rate at which the film is traveling.

(5): A sample is taken from the end of every roll and inspected

through the light box to verify there are no color deviations from

roll-to-roll.

(6): Once the entire order has been printed, the rolls of film are

delivered to either the laminating department or converting

department for the next phase of the production process.

7. What is your lead time for stand-up pouches?

YC Packaging works hard to get materials to you when you need them.

Please let our service team know your timelines and we will work

with you. Generally, on new orders, lead times are 4-9 weeks and on

repeat orders 3-7 weeks.

Raw material availability may impact these time frames.

8. Are you able to provide samples of premade pouches?

Yes, we have a wide variety of premade pouches that we can send

samples of, such as zipper pouches, slider pouches, spouted pouches

(also known as fitment pouches), stand-up pouches with windows,

shaped stand-up pouches, 3-side seal pouches, and our innovative

block bottom pouches.

We also provide pouch prototyping services.

9. What information is needed to place an order ?

It includes information on pouch size, quantity per sku, structure.

Artwork: Artwork files, PMS colors or samples of specific color

matches.